By continuously seeking new insights and staying abreast of industry trends, organizations can not only stay ahead of the curve but also position themselves as thought leaders within their respective fields.

In today's demanding work environments, success hinges on the ability to prioritize knowledge, quality, and trust. Companies that understand the strategic value of these core principles are better equipped to navigate the challenges and complexities of the modern business landscape. Knowledge is the foundation upon which informed decisions are made. By continuously seeking new insights and staying abreast of industry trends, organizations can not only stay ahead of the curve but also position themselves as thought leaders within their respective fields.

In Animek Shaurya’s role, he achieved significant milestones that underscore his strategic leadership and commitment to excellence. Notably, he is currently spearheading the successful implementation of SAP for Plant Maintenance and Material Master, ensuring a seamless transition and alignment with organizational objectives. Additionally, his initiatives in optimizing spare parts inventory management led to substantial cost savings and minimized downtime through strategic partnerships and efficient reordering strategies. Standardizing preventive maintenance programs further enhanced equipment reliability and minimized unplanned downtime, demonstrating his dedication to operational excellence. Through cross-functional collaboration and continuous improvement efforts, he facilitated knowledge transfer and skill development, fostering a culture of innovation and collaboration. Moreover, Animek’s focus on audit compliance and quality assurance ensured adherence to industry standards and regulatory requirements, bolstering organizational credibility. Leveraging digital tools and data analytics, he drove efficiency gains and operational visibility while empowering the workforce through comprehensive training and SOP development. These achievements reflect his continuous commitment to driving success through strategic initiatives and continuous improvement.

As a crucial member of the organization, his involvement and contributions have resulted in significant impacts across various aspects of the business, aligning with the scope covered in this article. Through strategic initiatives in spare parts optimization, including vendor negotiations and inventory reorganization, Animek achieved substantial cost savings amounting to approximately $100,000 annually, directly benefiting the organization's bottom line. Furthermore, his efforts in improving maintenance operations efficiency led to a notable 20% reduction in unplanned downtime, enhancing equipment uptime and productivity. By ensuring compliance with regulatory standards and consistently achieving high audit scores, he bolstered the organization's reputation for excellence in quality assurance. Additionally, proactive maintenance planning and cross-functional collaboration resulted in a 30% reduction in equipment breakdowns and a 20% increase in overall equipment effectiveness (OEE). Streamlining processes and fostering collaboration led to a 25% reduction in process lead times and improved coordination between departments. Through knowledge transfer initiatives and workforce development programs, he empowered employees with the necessary skills and knowledge, reducing training time for new hires and enhancing overall workforce capabilities. Overall, these impacts underscore his commitment to driving success and delivering measurable results within the organization.

In the expert’s capacity as a maintenance management professional, he spearheaded several impactful projects both within and outside the organization, showcasing his ability to drive strategic initiatives and deliver measurable results. Notable projects include the implementation of a Computerized Maintenance Management System (CMMS), optimization of spare parts inventory management, and management of large-scale equipment overhaul projects. Additionally, he played a key role in ensuring regulatory compliance, integrating the SAP Plant Maintenance (PM) module, and leading process improvement initiatives. These projects highlight my proficiency in driving efficiency, reliability, and compliance within maintenance operations. Furthermore, Animek’s works have resulted in desirable outcomes resulting in recognition of his organization, demonstrating the impact of his efforts. For instance, through vendor negotiations, he achieved significant cost savings of $70,000 for ribbons used in printers and reduced lead time by 8 weeks for sourcing specific parts. Efficiency improvements, such as a 20% reduction in spare parts search time and a 30% reduction in stockouts, have also been achieved. Moreover, his initiatives have optimized maintenance budgets, completing projects within allocated timelines and budgets while ensuring 100% compliance with regulatory standards. Overall, these achievements underscore Shaurya’s ability to drive cost savings, lead time reduction, efficiency improvements, budget optimization, adherence to regulatory standards, and timely project completion, showcasing his commitment to driving organizational success through strategic maintenance management initiatives.

Further mentioning Animek’s role within maintenance management, he encountered and effectively navigated various challenges, leading to significant achievements and positive outcomes. One such challenge involved transitioning from manual spare parts management to a digital system, overcoming resistance to change by providing comprehensive training and support. Additionally, he successfully established productive relationships with vendors, addressed data management inconsistencies, and introduced structured methodologies for project planning and execution. Facilitating cross-functional collaboration and implementing knowledge transfer programs were also key challenges that he addressed proactively. Furthermore, he ensured regulatory compliance and audit preparedness by implementing standardized procedures and training initiatives. By overcoming these challenges, he only improved operational efficiency and reliability and also fostered a culture of continuous improvement and innovation within the organization.

As an experienced professional in maintenance, reliability engineering, and spare parts management, Animek Shaurya cultivated unique insights shaped by hands-on involvement in diverse projects. He advocates for a proactive maintenance approach, emphasizing predictive analytics and condition monitoring to minimize downtime and optimize asset performance. Integration of digital solutions like CMMS and EAM platforms streamline operations and facilitate data-driven decision-making. Collaboration across departments fosters alignment and resource utilization while investing in training ensures skill continuity amid workforce changes. Embracing Industry 4.0 practices and sustainability initiatives aligns with evolving industry trends, driving efficiency and environmental responsibility. By adopting these strategies, organizations can navigate the complexities of modern maintenance landscapes and achieve sustained success.

![submenu-img]() This singer helped BCCI when it had no money to award 1983 World Cup-winning Indian cricket team, raised 20 lakh by...

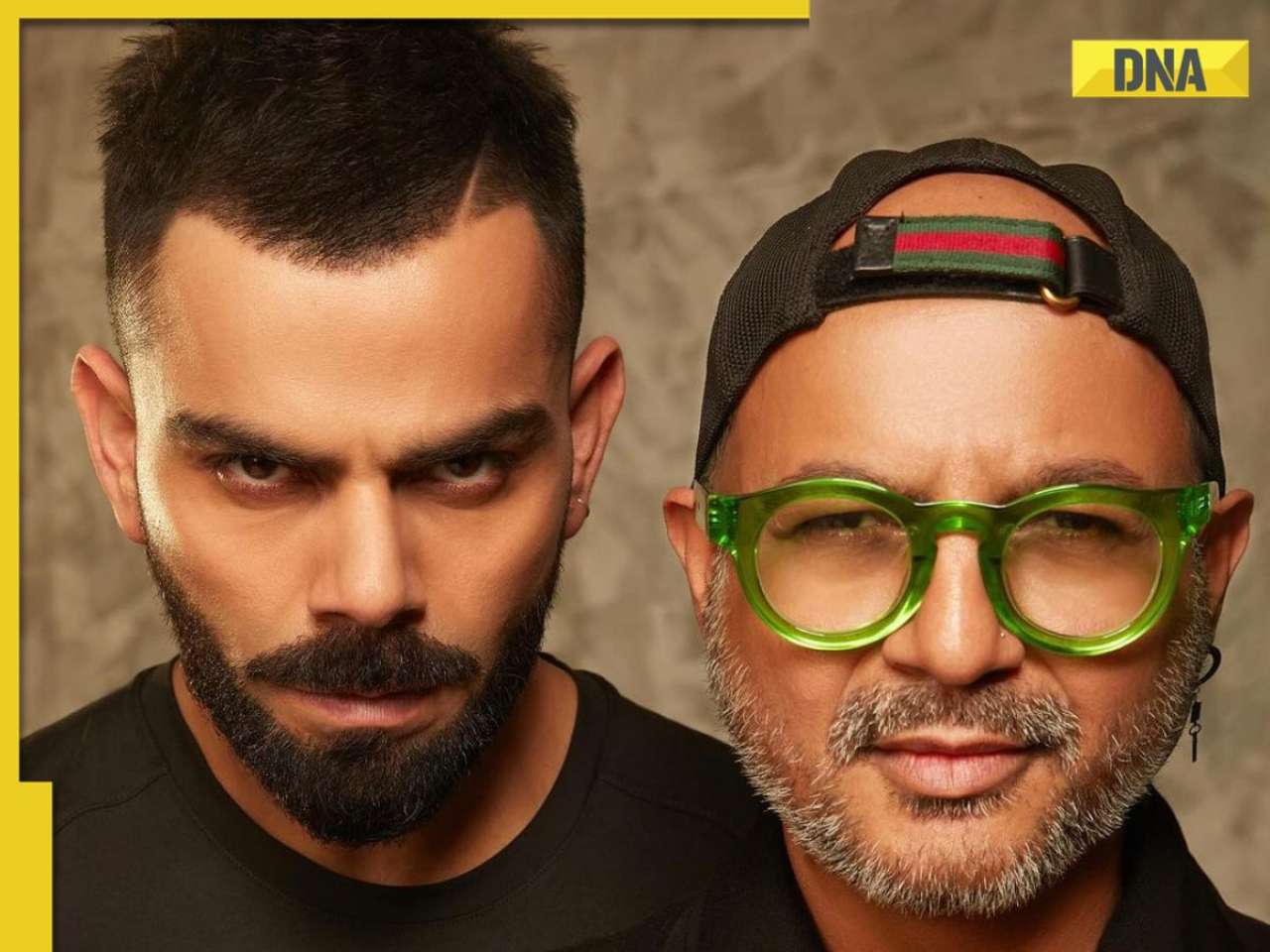

This singer helped BCCI when it had no money to award 1983 World Cup-winning Indian cricket team, raised 20 lakh by...![submenu-img]() Virat Kohli’s new haircut ahead of RCB vs CSK IPL 2024 showdown sets internet on fire, see here

Virat Kohli’s new haircut ahead of RCB vs CSK IPL 2024 showdown sets internet on fire, see here![submenu-img]() BCCI bans Mumbai Indians skipper Hardik Pandya, slaps INR 30 lakh fine for....

BCCI bans Mumbai Indians skipper Hardik Pandya, slaps INR 30 lakh fine for....![submenu-img]() 'Justice must prevail': Former PM HD Deve Gowda breaks silence in Prajwal Revanna case

'Justice must prevail': Former PM HD Deve Gowda breaks silence in Prajwal Revanna case![submenu-img]() India urges students in Kyrgyzstan to stay indoors amid violent protests in Bishkek

India urges students in Kyrgyzstan to stay indoors amid violent protests in Bishkek![submenu-img]() Meet IIT graduates, three friends who were featured in Forbes 30 Under 30 Asia list, built AI startup, now…

Meet IIT graduates, three friends who were featured in Forbes 30 Under 30 Asia list, built AI startup, now…![submenu-img]() Meet woman who cracked UPSC in fourth attempt to become IAS officer, secured AIR...

Meet woman who cracked UPSC in fourth attempt to become IAS officer, secured AIR...![submenu-img]() Meet IIT JEE 2024 all-India girls topper who scored 100 percentile; her rank is…

Meet IIT JEE 2024 all-India girls topper who scored 100 percentile; her rank is…![submenu-img]() Meet PhD wife of IIT graduate hired at Rs 100 crore salary package, was fired within a year, he is now…

Meet PhD wife of IIT graduate hired at Rs 100 crore salary package, was fired within a year, he is now…![submenu-img]() Meet woman not from IIT, IIM or NIT, cracked UPSC exam in first attempt with AIR...

Meet woman not from IIT, IIM or NIT, cracked UPSC exam in first attempt with AIR...![submenu-img]() DNA Verified: Is CAA an anti-Muslim law? Centre terms news report as 'misleading'

DNA Verified: Is CAA an anti-Muslim law? Centre terms news report as 'misleading'![submenu-img]() DNA Verified: Lok Sabha Elections 2024 to be held on April 19? Know truth behind viral message

DNA Verified: Lok Sabha Elections 2024 to be held on April 19? Know truth behind viral message![submenu-img]() DNA Verified: Modi govt giving students free laptops under 'One Student One Laptop' scheme? Know truth here

DNA Verified: Modi govt giving students free laptops under 'One Student One Laptop' scheme? Know truth here![submenu-img]() DNA Verified: Shah Rukh Khan denies reports of his role in release of India's naval officers from Qatar

DNA Verified: Shah Rukh Khan denies reports of his role in release of India's naval officers from Qatar![submenu-img]() DNA Verified: Is govt providing Rs 1.6 lakh benefit to girls under PM Ladli Laxmi Yojana? Know truth

DNA Verified: Is govt providing Rs 1.6 lakh benefit to girls under PM Ladli Laxmi Yojana? Know truth![submenu-img]() Kiara Advani stuns in Prabal Gurung thigh-high slit gown for her Cannes debut, poses by the French Riviera

Kiara Advani stuns in Prabal Gurung thigh-high slit gown for her Cannes debut, poses by the French Riviera![submenu-img]() Heeramandi star Taha Shah Badussha makes dashing debut at Cannes Film Festival, fans call him ‘international crush’

Heeramandi star Taha Shah Badussha makes dashing debut at Cannes Film Festival, fans call him ‘international crush’![submenu-img]() Streaming This Week: Madgaon Express, Zara Hatke Zara Bachke, Bridgerton season 3, latest OTT releases to binge-watch

Streaming This Week: Madgaon Express, Zara Hatke Zara Bachke, Bridgerton season 3, latest OTT releases to binge-watch![submenu-img]() Sunanda Sharma exudes royalty as she debuts at Cannes Film Festival in anarkali, calls it ‘Punjabi community's victory’

Sunanda Sharma exudes royalty as she debuts at Cannes Film Festival in anarkali, calls it ‘Punjabi community's victory’![submenu-img]() Aishwarya Rai walks Cannes red carpet in bizarre gown made of confetti, fans say 'is this the Met Gala'

Aishwarya Rai walks Cannes red carpet in bizarre gown made of confetti, fans say 'is this the Met Gala'![submenu-img]() Haryana Political Crisis: Will 3 independent MLAs support withdrawal impact the present Nayab Saini led-BJP government?

Haryana Political Crisis: Will 3 independent MLAs support withdrawal impact the present Nayab Saini led-BJP government?![submenu-img]() DNA Explainer: Why Harvey Weinstein's rape conviction was overturned, will beleaguered Hollywood mogul get out of jail?

DNA Explainer: Why Harvey Weinstein's rape conviction was overturned, will beleaguered Hollywood mogul get out of jail?![submenu-img]() What is inheritance tax?

What is inheritance tax?![submenu-img]() DNA Explainer: What is cloud seeding which is blamed for wreaking havoc in Dubai?

DNA Explainer: What is cloud seeding which is blamed for wreaking havoc in Dubai?![submenu-img]() DNA Explainer: What is Israel's Arrow-3 defence system used to intercept Iran's missile attack?

DNA Explainer: What is Israel's Arrow-3 defence system used to intercept Iran's missile attack?![submenu-img]() This singer helped BCCI when it had no money to award 1983 World Cup-winning Indian cricket team, raised 20 lakh by...

This singer helped BCCI when it had no money to award 1983 World Cup-winning Indian cricket team, raised 20 lakh by...![submenu-img]() This film had 3 superstars, was unofficial remake of Hollywood classic, was box office flop, later became hit on...

This film had 3 superstars, was unofficial remake of Hollywood classic, was box office flop, later became hit on...![submenu-img]() Meet Nancy Tyagi, Indian influencer who wore self-stitched gown weighing over 20 kg to Cannes red carpet

Meet Nancy Tyagi, Indian influencer who wore self-stitched gown weighing over 20 kg to Cannes red carpet![submenu-img]() Telugu actor Chandrakanth found dead days after rumoured girlfriend Pavithra Jayaram's death in car accident

Telugu actor Chandrakanth found dead days after rumoured girlfriend Pavithra Jayaram's death in car accident![submenu-img]() Meet superstar who faced casting couch at young age, worked in B-grade films, was once highest-paid actress, now..

Meet superstar who faced casting couch at young age, worked in B-grade films, was once highest-paid actress, now..![submenu-img]() Viral video: Flood-rescued dog comforts stranded pooch with heartfelt hug, internet hearts it

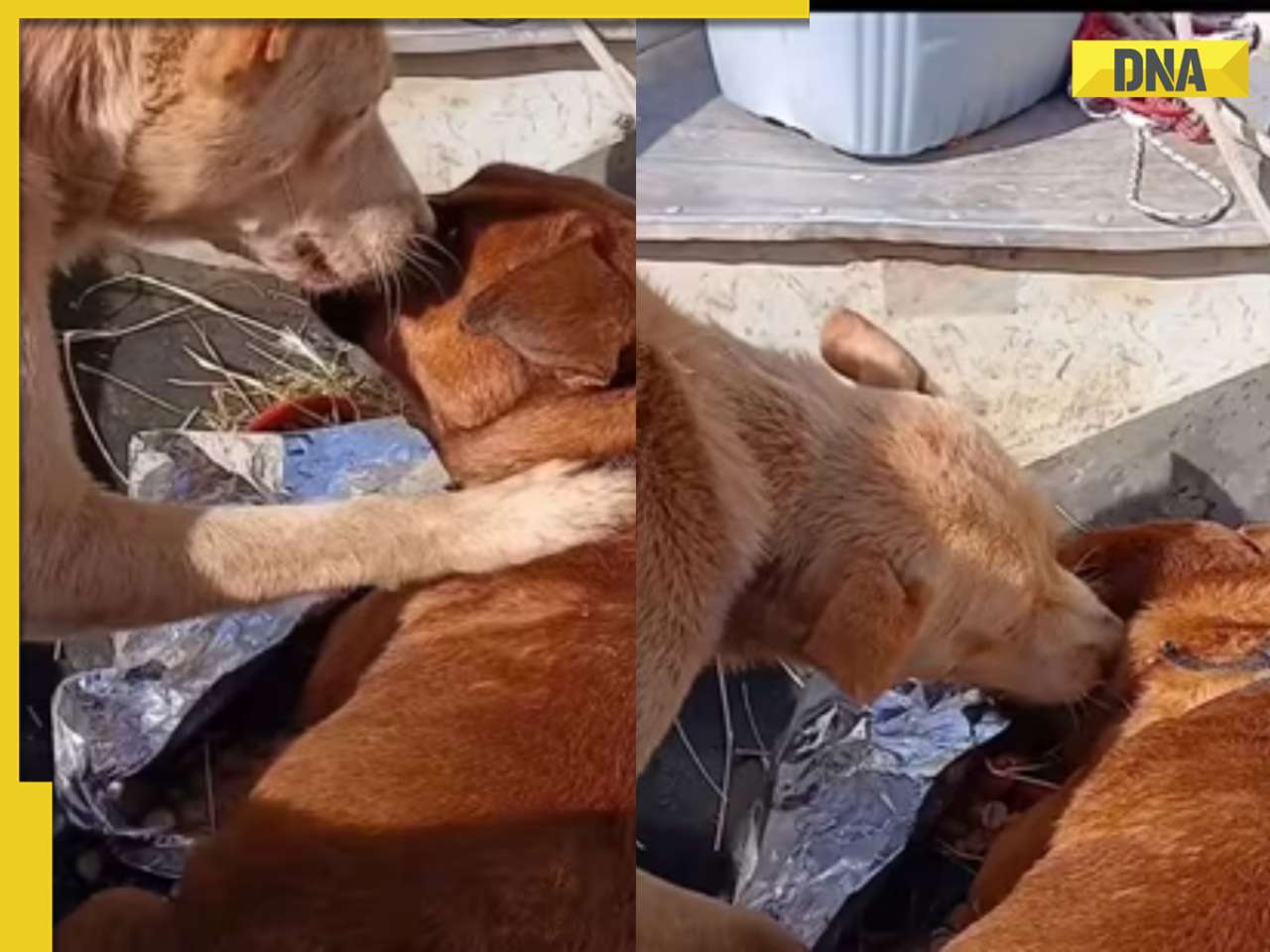

Viral video: Flood-rescued dog comforts stranded pooch with heartfelt hug, internet hearts it![submenu-img]() Dubai ruler captured walking hand-in-hand with grandson in viral video, internet can't help but go aww

Dubai ruler captured walking hand-in-hand with grandson in viral video, internet can't help but go aww![submenu-img]() IPL 2024: Virat Kohli drops massive hint on MS Dhoni’s retirement plan ahead of RCB vs CSK clash

IPL 2024: Virat Kohli drops massive hint on MS Dhoni’s retirement plan ahead of RCB vs CSK clash![submenu-img]() Do you know which God Parsis worship? Find out here

Do you know which God Parsis worship? Find out here![submenu-img]() This white marble structure in Agra, competing with Taj Mahal, took 104 years to complete

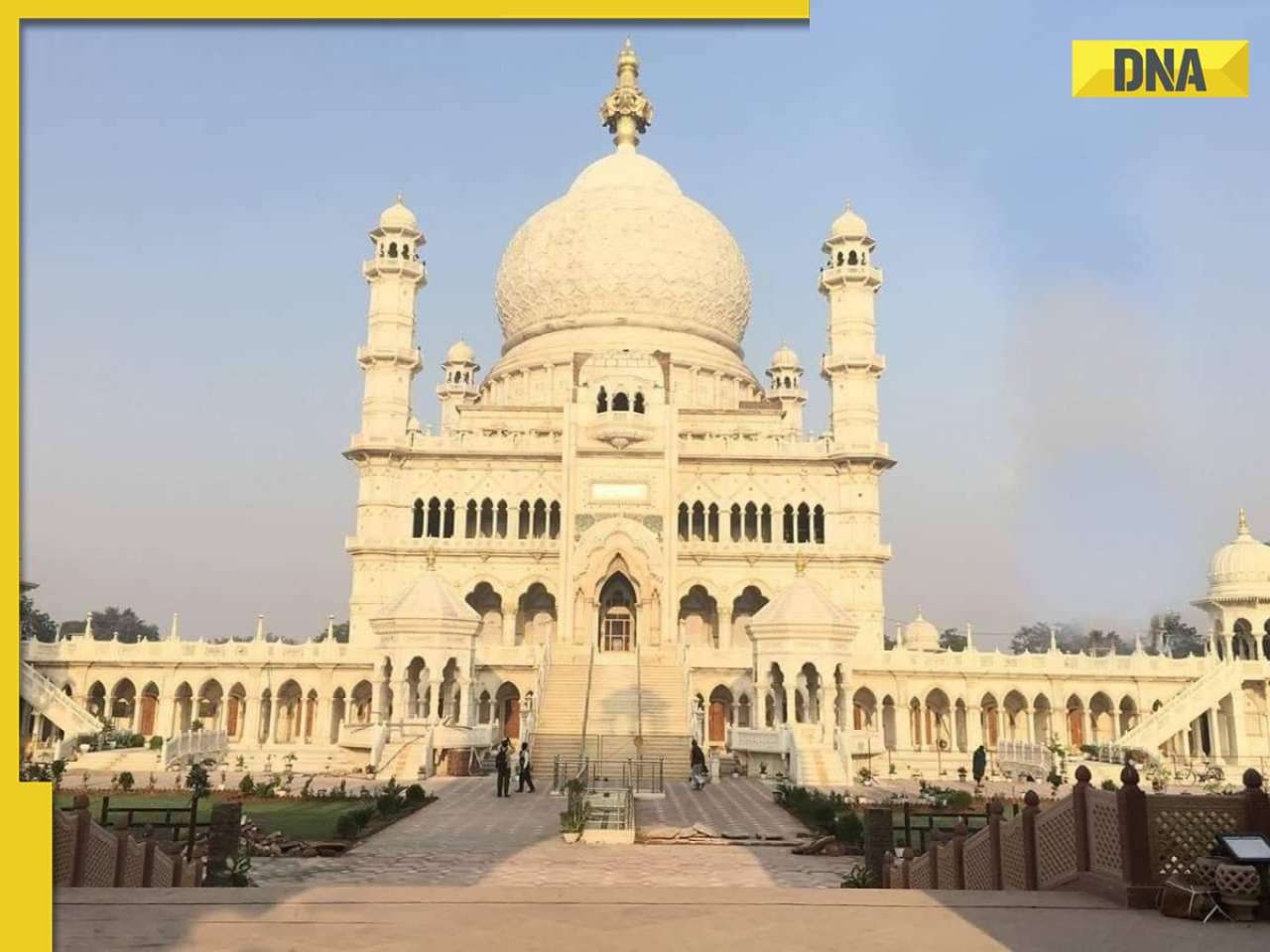

This white marble structure in Agra, competing with Taj Mahal, took 104 years to complete

)

)

)

)

)

)

)